Automatic Lubrication Systems

Automatic lubrication of components such as bearings, gears, pins, and bushings saves many hours of manual lubrication. Also, it allows the equipment to be lubricated during operation or driving, which is a significant advantage. This means the maintenance personnel does not have to constantly be present on-site or crawl under and climb over the equipment to lubricate hard-to-reach points. The automatic lubrication system is a smart investment in truck availability, efficiency, productivity, and safety. Together with the extended life span of crucial components, these benefits ensure that the Groeneveld automatic lubrication system has a quick return on investment.

Automatic Lubrication

Benefits at a Glance

- Enhanced lifetime of pivots, bearings, pins and bushings

- Reduced repair and maintenance costs

- Reduced grease consumption (up to 50%)

- Enhanced uptime and machine productivity

- Higher residual value of machine or vehicle

Automatic Lubrication

Services & Parts

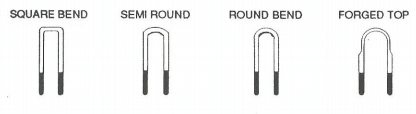

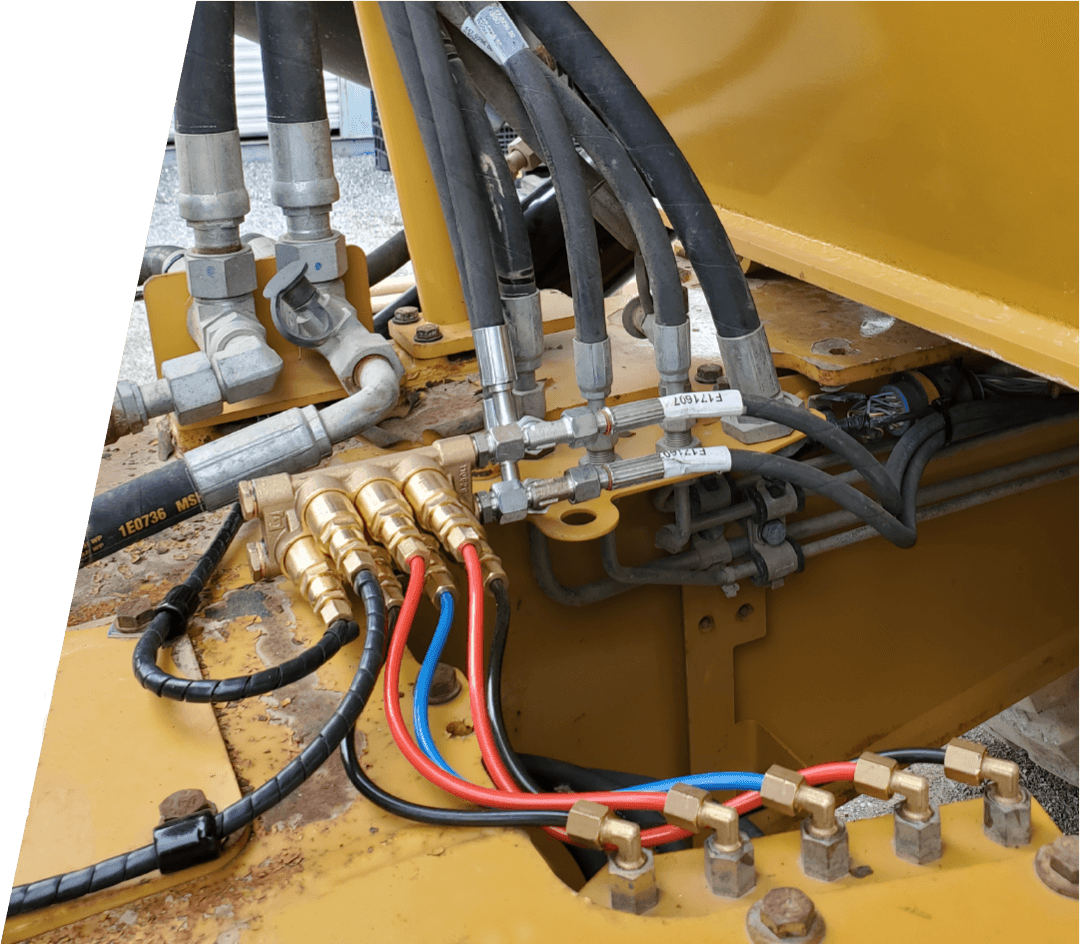

- Fittings

- Injectors

- Lines

- Pumps

- Reservoirs

- Systems/Installs

Brands We Work With

The Mine Safety and Health Administration, a United States Department of Labor agency, promotes safe, healthful mining workplaces, and prevents mining deaths, illnesses and injuries.

MSHA Part 48 training is mandatory training received by miners, supervisors, construction workers and independent contractors who work at mining operations. Our field technicians have completed and maintain certification of Part 48 training. This gives them the ability to provide on-site service of surface and underground mining equipment for the quarry and aggregates industries including pit loaders, front shovels, dozers, off-highway trucks, excavators, articulated trucks, yard loaders and engines/generator sets.