Custom Leaf Springs

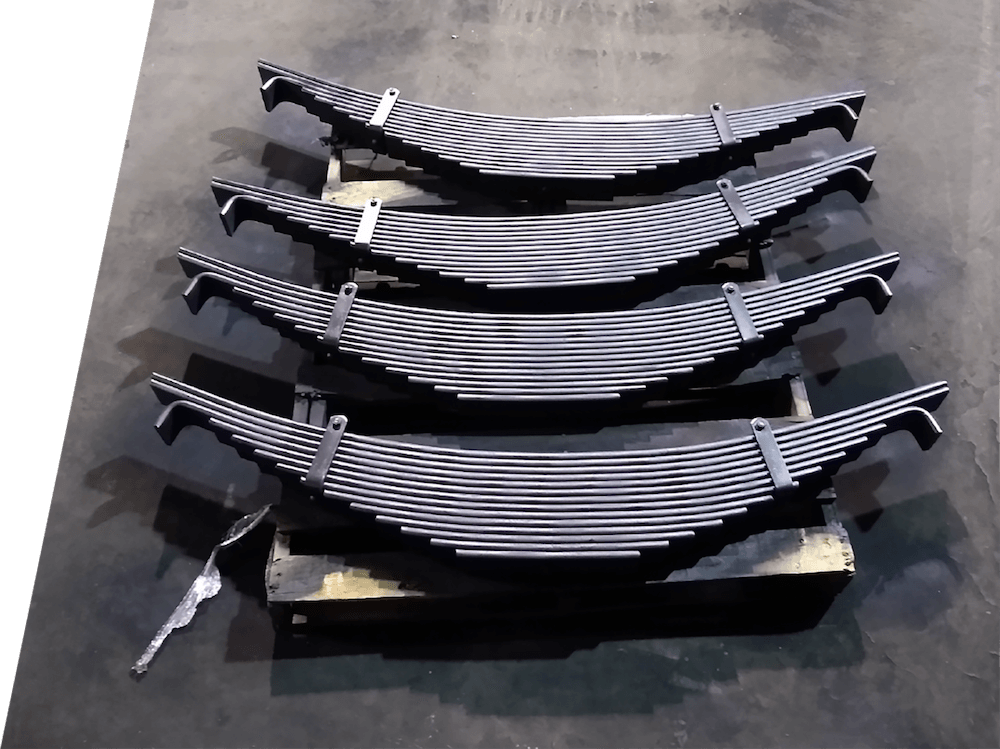

Manufacturing OEM quality leaf springs is a specialty. With over 50 years of experience and a manufacturing facility located in central Ohio, we manage projects from single custom springs to OEM production runs and everything in between. We are renowned for our craftmanship and manufacturing capabilities, and take pride in what we make.

Custom Leaf Springs

Applications

- Specialty – Trolleys, Rail Cars, Trailers, Buses, Semi-Tractors, Classic Cars, Hot Rods, Historic, Vintage, Farm Tractors, Mine Equipment, Athletic Equipment

- Custom – Custom vehicles, custom ride height, off-road vehicles

- Obsoleted OEM Replacement – hard to find for historic, vintage, and classic vehicles from manufacturers such as Studebaker, Duesenberg, Auburn, Hudson, Packard

- OEM – quantities from one to hundreds

Custom Leaf Springs

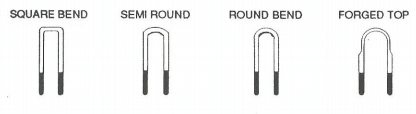

Manufacturing Capabilities

- Maintain an extensive library of original equipment blueprints

- Complete in-house manufacturing – shear, punch, furnace, forming, heat treat, assembly, and paint

- Utilize high quality 5160 alloy spring steel and grade 8 hardware

- Semi gloss black industrial acrylic finish, custom finishes available

“Hands down the best place to get service when it comes to leaf springs. The professionalism from customer service was excellent. The job was completed in a timely manner and pricing was very reasonable.” - Rebekah W.

“I dropped off my trailer with a broken spring in the morning and picked it up at the end of the day. Great service and a fair price. Thank you for the quick turnaround.” - Steve W.

Previous

Next

Request a Quote

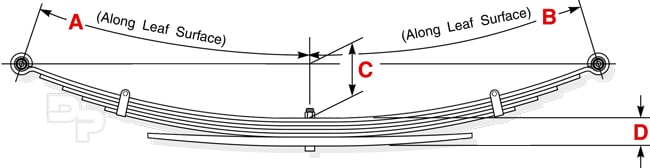

Fill out the form below to request a quote for your custom leaf springs. For more information on how to measure your leaf springs, please click here. To download printable instructions, click here.